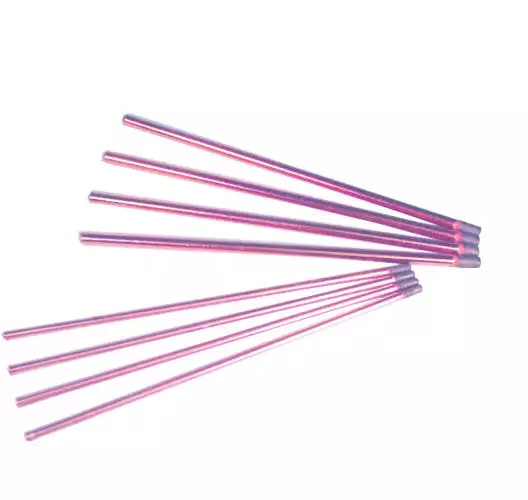

Gouging Rods -High-Quality Gouging Rods and Carbons for Precision Metal Work

Orders OVER £75 (Excluding VAT)

Orders UNDER £75 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Gouging Rods -High-Quality Gouging Rods and Carbons for Precision Metal Work

£9.95 – £22.50

Gouging Rods or gouging carbons have a a high metal removal rate. Available in different sizes.

Orders OVER £75 (Excluding VAT)

Orders UNDER £75 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Have a Question? Ask a Specialist

Low Prices

Price match guarantee

Wide range of products available

Always the correct part

In-House Experts.

We know our products

Easy Returns.

Quick & Hassle Free

Gouging Rods/Gouging Carbons Boxes of 50

In the air carbon arc process, gouging carbons consist of carbon rods coated with copper for cutting, gouging, and removing weld defects.

The 305mm long pointed carbon gouging rods are available in diameters of 4,5, 6.4, 8, 10 and 12.7mm. -50 rods per box

The electrode diameter should be selected according to the depth and width of the project.

Elevate your metalworking projects with our premium Gouging Rods and Carbons, designed for professionals and enthusiasts seeking precision and efficiency in gouging tasks. These top-tier gouging tools offer unmatched performance in removing metal, cutting, and preparing welds, ensuring a clean, accurate finish every time. Suitable for a variety of metals, including cast iron, our gouging rods and carbons are essential for anyone aiming for perfection in their metalworking or welding projects.

What is carbon arc gouging?

Carbon arc gouging is a process used extensively in the metalworking and welding industries to remove metal, cut, and prepare welds. It involves the use of a carbon electrode to generate an electric arc between the electrode and the workpiece. The intense heat of the arc melts the metal, while a jet of compressed air is used to blow the molten metal away from the cut or gouge area.

The process is particularly valued for its ability to precisely remove metal without affecting the integrity of the remaining structure. It’s commonly used for tasks such as removing defective metal, preparing weld edges, cutting metal, making grooves for welds, and cleaning out cracks before repair work. Carbon arc gouging offers several advantages, including speed, efficiency, and the ability to work on a variety of metals, such as steel, cast iron, and stainless steel. It requires a power source capable of providing a high current, a carbon electrode, and air supply equipment to perform the gouging operation.

What polarity do you gouge with?

Gouging is most commonly performed using direct current electrode negative (DCEN) polarity. This setup ensures efficient metal removal, minimal electrode wear, and optimal control during the gouging process. Our Gouging Rods and Carbons are compatible with all standard DCEN setups, providing you with a seamless and effective gouging experience.

How loud is carbon arc gouging?

Carbon arc gouging can be quite loud, often reaching noise levels similar to heavy machinery. It’s essential to use appropriate hearing protection during gouging operations to safeguard your hearing. Despite the noise, our Gouging Rods and Carbons ensure a smooth and efficient metal removal process, making them a valuable tool in any metalworking arsenal. Disadvantages are that the air jet causes the molten metal to be ejected over quite a large distance and, because of high currents (up to 2000A) and high air pressures (80 to 100 psi), it can be very noisy.

What are gouging carbons used for?

Gouging carbons are specialized electrodes used in the carbon arc gouging process. They are designed for cutting and removing metal, preparing weld edges, and cleaning defects in welds or castings. Our gouging carbons are made from high-quality materials, ensuring effective performance in a wide range of applications, from heavy fabrication to maintenance and repair work.

Can you gouge cast iron?

Yes, you can gouge cast iron using our high-quality Gouging Rods and Carbons. Gouging cast iron requires precise control and effective tools, and our products are designed to handle the challenges of gouging this type of metal, providing clean, accurate results without damaging the material.

How does gouging work?

Gouging works by using a high-temperature electric arc generated between the gouging carbon or rod and the workpiece. This arc melts the metal, while a jet of compressed air blows the molten metal away, creating a groove or cut. The process allows for precise removal of metal, preparation of weld edges, and cleaning of defects. Our Gouging Rods and Carbons are engineered for optimal performance, ensuring a smooth gouging process and exceptional results.

With our Gouging Rods and Carbons, achieve unparalleled precision and efficiency in your metalworking projects. Whether you’re preparing weld edges, cutting metals, or cleaning welds and castings, our products offer the reliability and performance you need to excel in your craft.

To learn more about arc air gouging rods, please see this article from TWI-Global.

If you require a gouging torch, please click here.