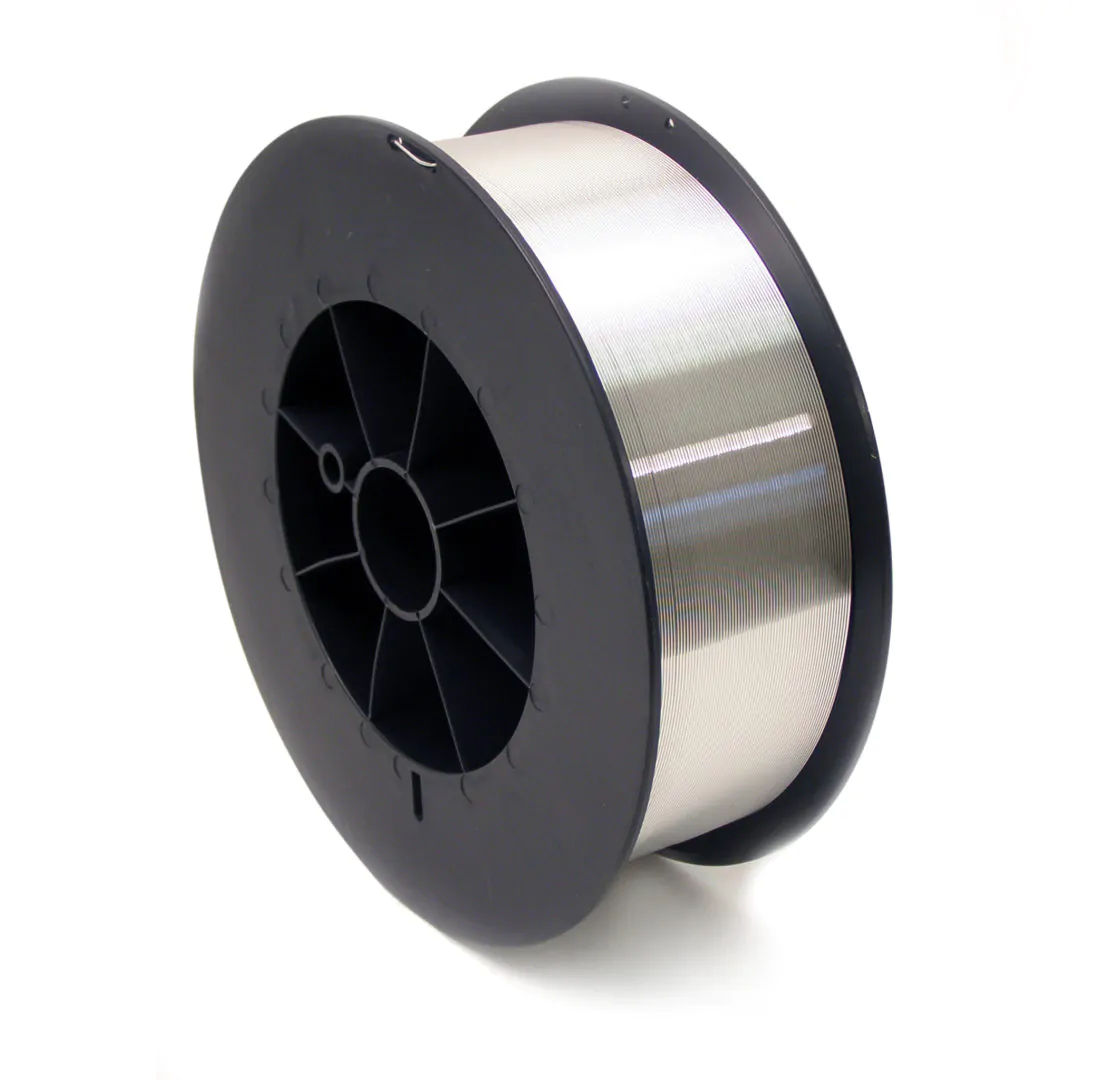

Aluminium MIG Wire 5356 6kg Spool Good Quality Wire

Orders OVER £75 (Excluding VAT)

Orders UNDER £75 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Aluminium MIG Wire 5356 6kg Spool Good Quality Wire

£61.90 – £65.45

Aluminium mig wire 5356 6kg spool is a general-purpose aluminium wire with 5% magnesium that has excellent corrosion resistance and high strength. Great Quality

Orders OVER £75 (Excluding VAT)

Orders UNDER £75 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Have a Question? Ask a Specialist

Low Prices

Price match guarantee

Wide range of products available

Always the correct part

In-House Experts.

We know our products

Easy Returns.

Quick & Hassle Free

Aluminium MIG Wire 5356 6kg Spool

Aluminium mig wire 5356 6kg spool is a general-purpose aluminium wire with 5% magnesium that has excellent corrosion resistance and high strength. Suitable for welding magnesium bearing aluminium alloys such as 5251 (N4), 5154 (N5), 5454 (N51) and also heat treatable alloys 6063 (H9), 6061 (H20) and 6082 (H30). Suitable for anodising . 6 kg spool available in different diameters, see drop down.

What you need to know when you are welding with aluminium mig wire?

The key to successful aluminum welding:

The Right Equipment — Aluminum in its pure form is a relatively soft metal that has many uses, but which requires the addition of alloy(s) to increase its strength. Because aluminum’s properties vary greatly from steel, working with the material can present some unique challenges – such as distortion and sensitivity to heat input. Despite these issues, MIG welding aluminum isn’t that difficult when you use the right equipment. To see all the recommendations when welding aluminium , please read this helpful article from Millerwelds Guide to Aluminium Welding

Keep it clean: Aluminum should be thoroughly cleaned prior to welding, including the removal of any lubricants from the material. Oxide removal should be done after degreasing using a stainless wire brush – either a hand wire brush or a cup wire brush will work. If a power wire brush is used, keep the rpms and pressures low to reduce smearing the surface of the material, which could entrap oxides and impurities under the surface. To avoid contaminating the base material, always clean with a wire brush that is used on aluminum only.

Choose the right gas: Because aluminum is a non-ferrous metal, it requires a 100 percent argon shielding gas.

The right filler metal: Know the alloy of your base aluminum and what conditions the finished part will be subjected to. The two most readily available aluminum filler wires are ER4043 and ER5356. Click on the highlighted article if you want to know What Aluminium Wire to Use

Our Best Tip: Use “U” groove drive rolls, teflon liner, keep the mig torch as short and straight as possible.

In any welding application there are health risks, remember to protect yourself with an Air Fed Welding Helmet

5% Magnesium